Ipe Deck Fasteners -

( Ipe Clip™ , EB-TY™ etc.)

Ipe Deck Fasteners: Preferred Method

Fastening your Ipe Deck Down:

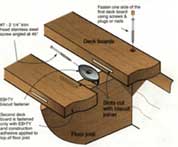

By far the most common method of installation, is with the

use of stainless steel screws (minimum 2 1/4"), inserted

from the top of the ipe decking, down into the structural

frame ....preferring #305 Stainless steel, because they have

the highest nickel content, for maximum weather and corrosion

resistance. Dipping the screws in paraffin wax, prior to installation,

will allow for easier insertion, and the wax will seal the

hole. Ipe wood plugs can be glued into the screw holes, (with

waterproof polyurathane glue) if the customer desires... just

make sure the countersink holes have been predrilled the correct

size for available plugs.

Some contractors prefer using a Trim Head screw because the head is much smaller and thus less noticeable on the upper deck surface .. in residential applications this provides enough holding power. Typically the hole is predrilled fractionally larger (5/32" for a #7 TH screw) to allow the screw to countersink itself slightly below the surface.

In industrial/commercial applications it is recommended that you stick with the traditional screws that have a larger, stronger head configuration, and then predrill a 9/64" hole for a #7 stainless steel screw. It is suggested, a minimum 2 1/2" screw length be used in these ipe deck applications.

It is necessary to install 2 screws into the joist across the face of either the 4" or 6" ipe decking. Some very meticulous woodworkers, especially in brutal environments, will apply exterior grade construction glue to the joist, prior to screwing down the ipe boards.

Hidden Fastening Systems:

Hidden fastening systems like Deck Master™ can be used,

but harder to install when drilling up into the wood. In any

situations where a board is twisting, it is impossible to

use your body weight, to assist in fastening it securely.

New systems are being designed daily. The most widely distributed are the Ipe Clip™ and the EB-TY™. See below for links to these two companys that have designed a special blind fastening system for Ipe decking:

|

|

|

Galvanized Fasteners:

Note that Galvanized Nails, brackets or fasteners, will turn

the wood black. If the contact point is hidden under the deck

then its not a cosmetic issue, but make sure in any application,

it will be hidden. Ultimately recognize that this chemical

corrosion will offer a shorter life expectancy.

Gluing Ipe Lumber:

Very dense woods like ipe are somewhat difficult to glue and

we have generally recommended epoxy type glues. It is highly

recommend that when using any type of glue that sample bonds

be made and tested before use in any project.

More Information:

Information on Ipe deck cleaning

and ipe sealers to maintain the colour and sustain the

wood.